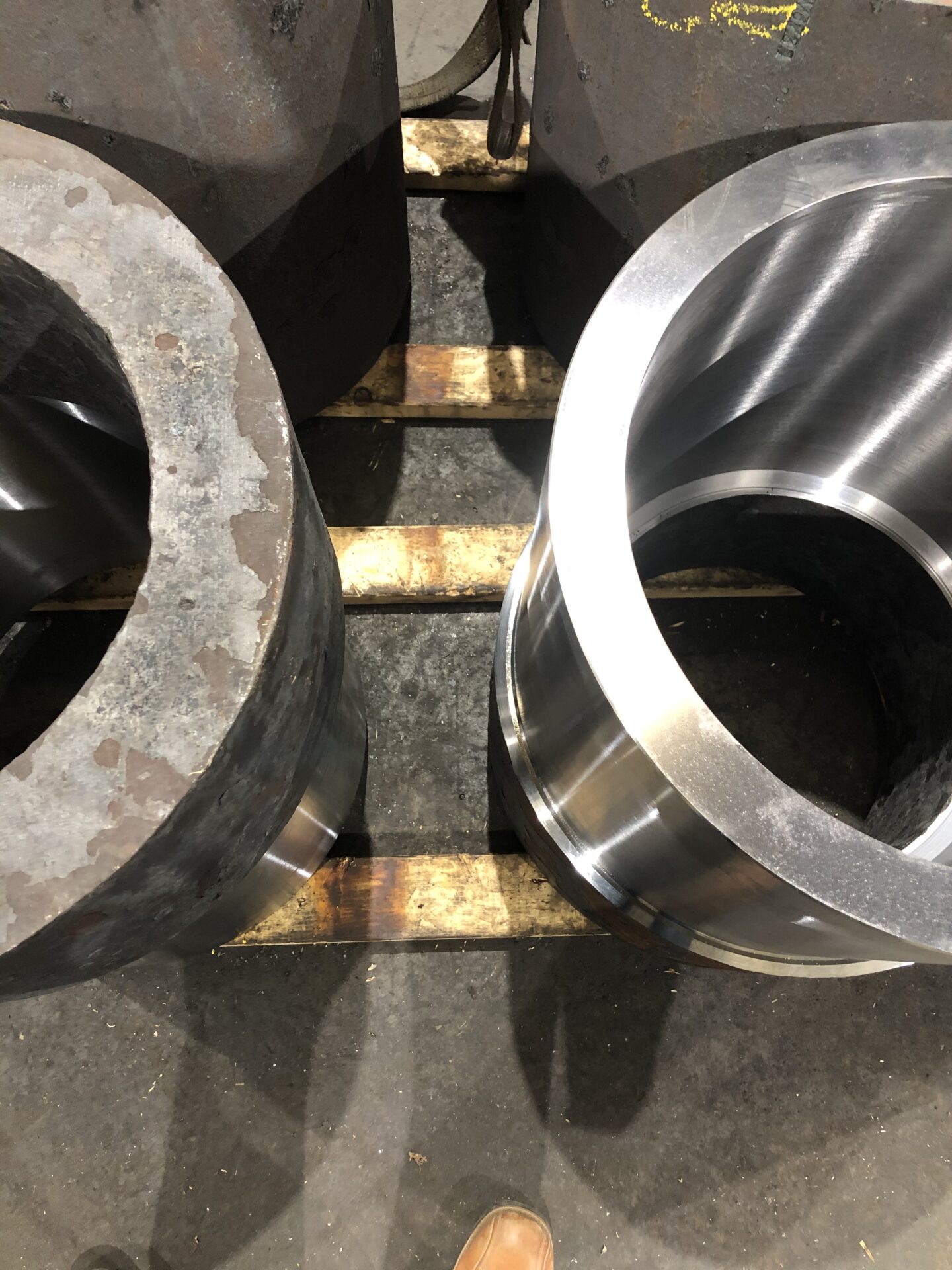

At the James L Tracey company we partner with the best manufacturing companies around. Whether you need machining (large or small parts), steel castings, forgings, fabrications, no problem. We can offer castings and forgings machined complete. If you need custom molded injection parts, we can do it.

About Us

James L Tracey Company is a family-owned and operated business based in Aurora, Illinois. We pride ourselves on our honesty and integrity, and we firmly believe that you'll see the difference when you choose our company. If you are looking for machining of large castings, forgings, or weldments, we can help.

Services

D&S Machine

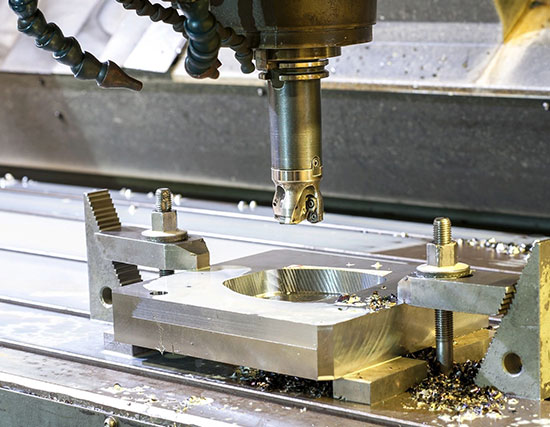

D&S Machine Service is a facility with more than 100 years of combined machining, fabrication, and engineering experience. D&S Machine Service's top commitment is towards the quality of our parts, services, and customer satisfaction.

We take advantage of single manufactured components to large multi-component assemblies. Free, fast, and competitive quotes are available upon request.

At D&S, we offer affordable pricing on larger quantity orders.

Kenosha Steel Castings

Kenosha Steel Castings is a full-service steel foundry producing castings up to 8,500 lbs. in weight and in flasks up to 10 ft. square.

Alloys poured range from plain carbon steel to high grades of 165,000 and 150,000 psi tensile and yield strengths respectively. Custom designed alloys and heat treatments can be designed to meet individual requirements.

Full-Service Capabilities

What We Offer